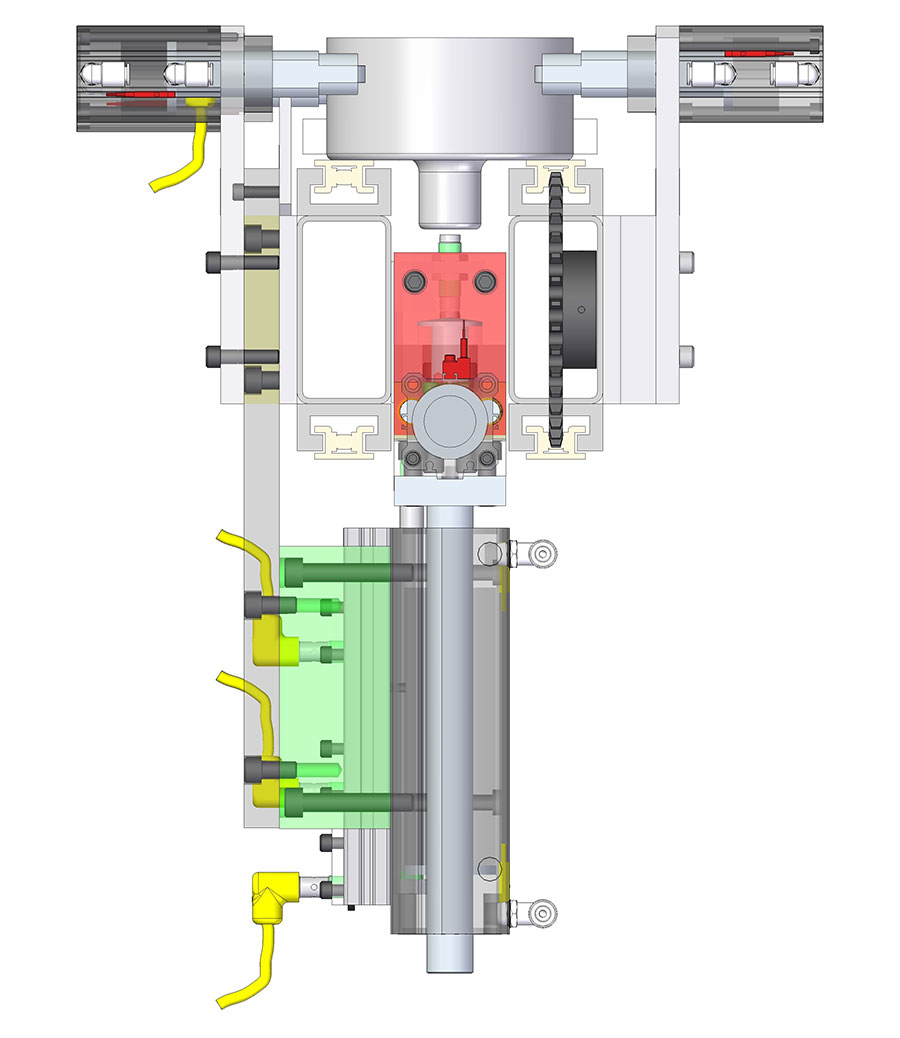

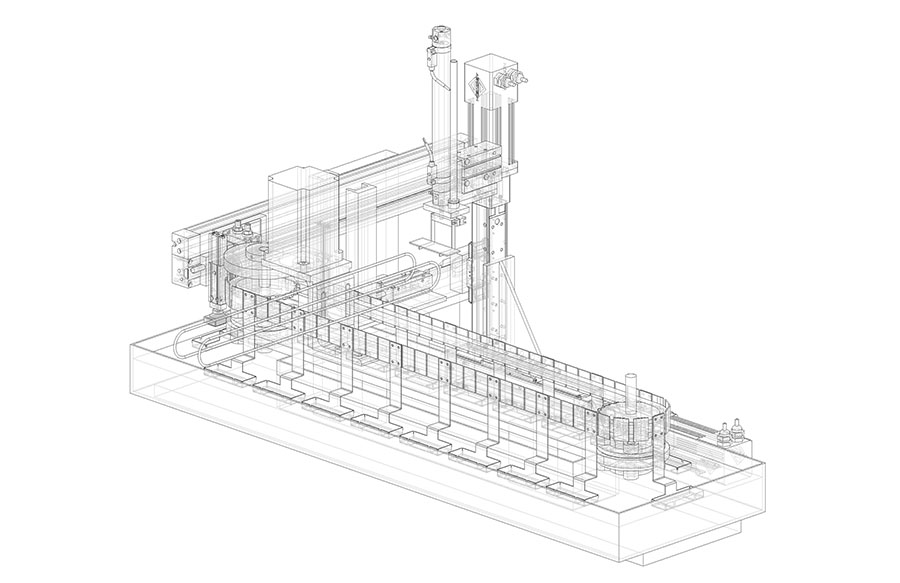

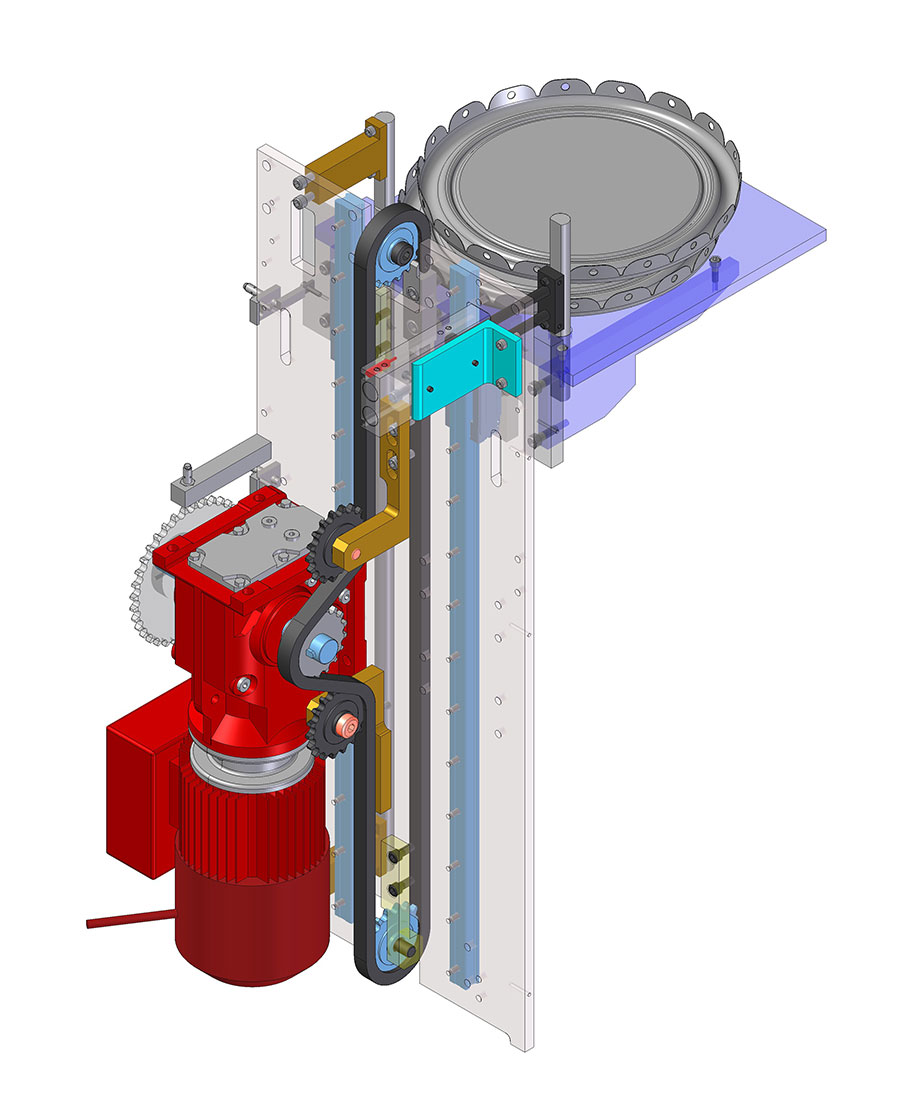

We offer a full range of mechanical design services, including the design of custom machines, automated equipment, jigs and dies, etc. Our engineers use state-of-the-art mechanical CAD software.

In our design process we use SOLID EDGE software from EDS that includes the following packages: Solid Modeling, Sheet Metal, Weldments, Assembly Modeling, Drafting, Motion Analysis and Design Data Management. Our work can be delivered in the form of CAD drawings or as computer data in native SOLID EDGE formats, UG format *.prt, Parasolid format *.x_t and *.x_b and a variety of other formats, including *.dwg, *.stp, *.igs and *.sat.

We also help clients with drawing conversions and create or update technical documentation.

Here are some examples of Mechanical CAD Services we offer: